Here I show the 6 oz fiberglass cut to fit. Interior has been sanded and vacuumed.

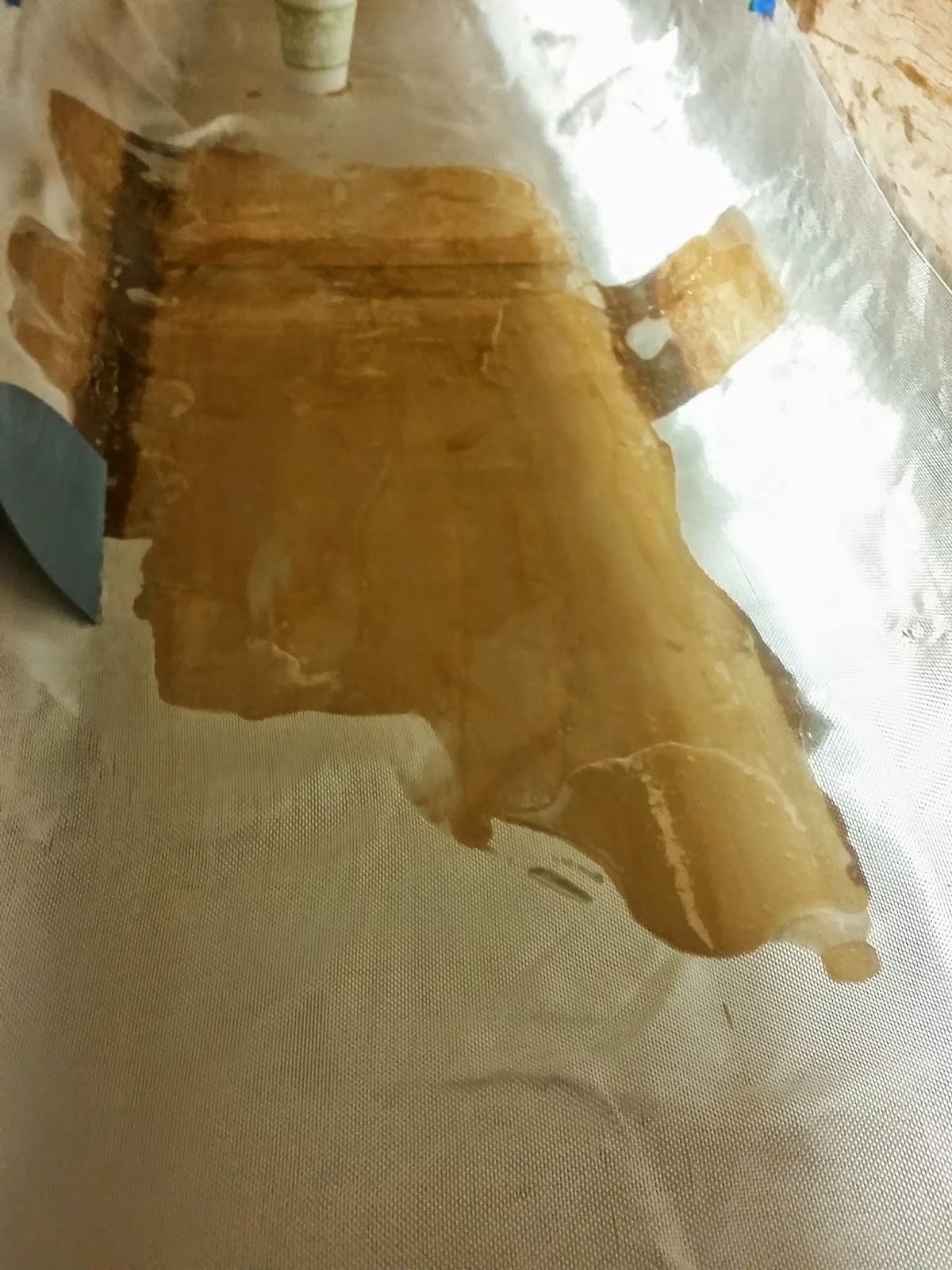

Here is a picture you don't often see. That is because most people work alone and once you start spreading epoxy, you can't stop. I had to take my gloves off to get this shot. Anyway, as you can see, the epoxy is partially spread.

This is about 2 hours after it was all spread. The epoxy has now dried so that it is still sticky but not fully cured. See the texture of the weave showing. Now is the time to spread on a second coat to fill the weave.

And here we are the next morning. See how shiny it is. Like glass. The boat is now tough, tough, tough.

No comments:

Post a Comment